Discover tailored solutions built for performance and reliability.

Connect with usDJK offers a Heat Recovery Unit tailored for pharmaceutical systems where 100% fresh air and energy efficiency are critical.

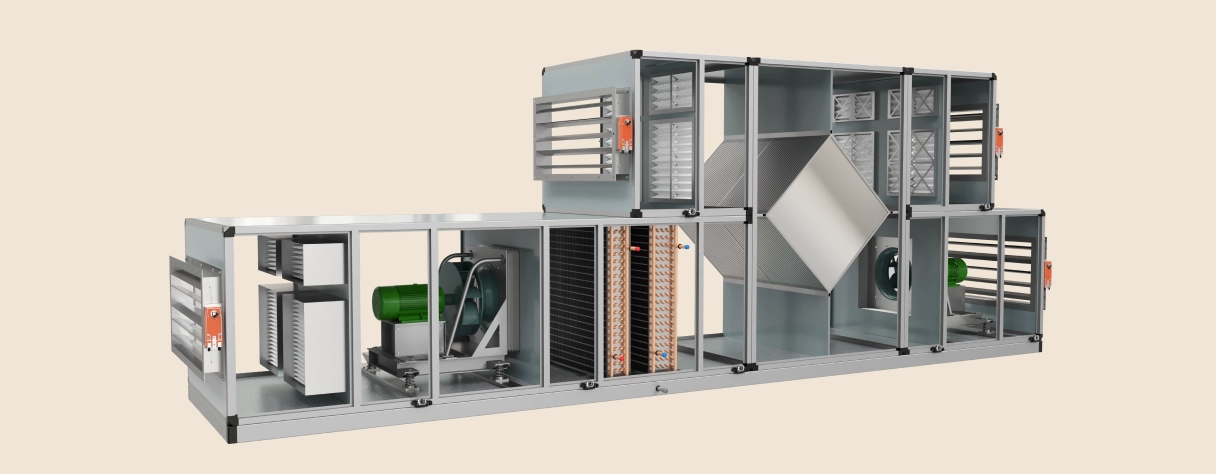

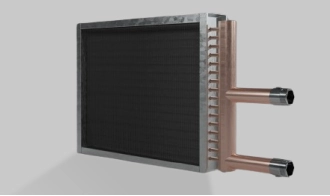

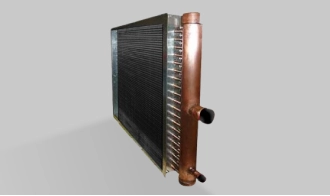

DJK’s Heat Recovery Unit is designed to recover heat from return air and transfer it to the incoming fresh air, reducing energy consumption and HVAC load. It is ideal for pharmaceutical applications where 100% fresh air, temperature control, and hygiene are essential. DJK offers the unit in three configurations — crossflow plate heat exchanger, heat recovery wheel, and heat pipe — to suit different project needs and performance requirements. Built for reliability and efficiency, the system ensures long-term, energy-saving operation.

Recovers heat from return air and transfers it to incoming fresh air, achieving up to 85% thermal efficiency and significant energy savings.

Engineered to prevent mixing of fresh and exhaust air—critical for cleanroom and pharma-grade applications.

Reduces load on HVAC systems, leading to lower energy consumption and operating costs.

Designed specifically for applications that require 100% fresh air, such as pharmaceutical facilities, cleanrooms, and other contamination-sensitive environments.

The unit can be customized based on required airflow, static pressure, and layout constraints to suit specific project requirements.

Available with Crossflow Plate Heat Exchanger, Heat Recovery Wheel, and Heat Pipe to suit different requirements.

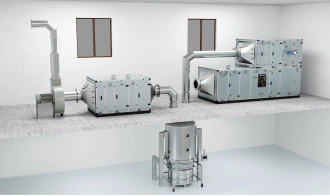

The Air Processing Unit (APU) plays a critical role in pharmaceutical granulation processes, ensuring optimal air quality and precise temperature control for equipment such as Fluid Bed Dryers (FBD) and Coating machines.

Know more

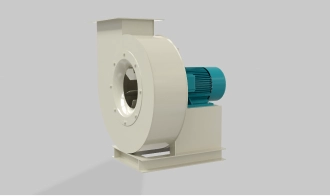

DJK offers the SWSI backward curved/radial blade non-overloading centrifugal blower, perfect for general HVAC applications.

Know more

Our wide range of heat exchangers and coils are selected using computerized selection program to obtain psychometric efficiency with low air and water pressure drop.

Our packing, dispatch, installation, and maintenance process ensures efficient handling of our product.

We pack each unit firmly and securely, tailored to customer requirements — whether in fully assembled, semi-knocked-down, or completely knocked-down condition. Timely dispatch ensures smooth delivery, and our expert installation team installs on-site, ensuring proper setup and functionality.

Safeguard your products, enhance production, and minimise risk with our precision-engineered HVAC solutions for the pharmaceutical and food industries.